Welding is crucial in Southeast Asia’s rapidly growing construction and fabrication industries, ensuring the durability of infrastructure projects like buildings, bridges, pipelines, and utilities. As large-scale projects increase, the demand for skilled welders and efficient welding solutions also rises, creating a need for innovative technologies to improve productivity and quality.

Addressing Labor Shortages and Efficiency Gaps

Southeast Asia faces a shortage of skilled welders, compounded by the need to optimize welding processes for faster project completion. Companies are turning to advanced welding technologies to enhance efficiency, reduce costs, and improve quality.

Key Welding Technologies for Southeast Asia:

1. Auto-Line™ Technology

Miller® power sources with Auto-Line™ offer stable, powerful arcs, even with fluctuating voltage, ensuring consistent results in areas with unreliable power grids. This reduces downtime and enhances project output by allowing more machines to run on the same electrical system.

2. ArcReach®

ArcReach® enables operators to adjust welding parameters remotely, reducing trips to the power source and saving time. It also improves safety by limiting unnecessary movement and ensures consistent arcs through cable length compensation (CLC™).

3. Advanced MIG welding Processes

The XMT 400, paired with the Miller Smart Feeder, supports advanced MIG welding processes such as Regulated Metal Deposition (RMD™) and Miller Pulsed MIG, enabling seamless welding across a wide range of base materials, including carbon steels, CrMo steels, stainless steels, and nickel alloys. This versatility makes it an excellent choice for both structural and piping applications.

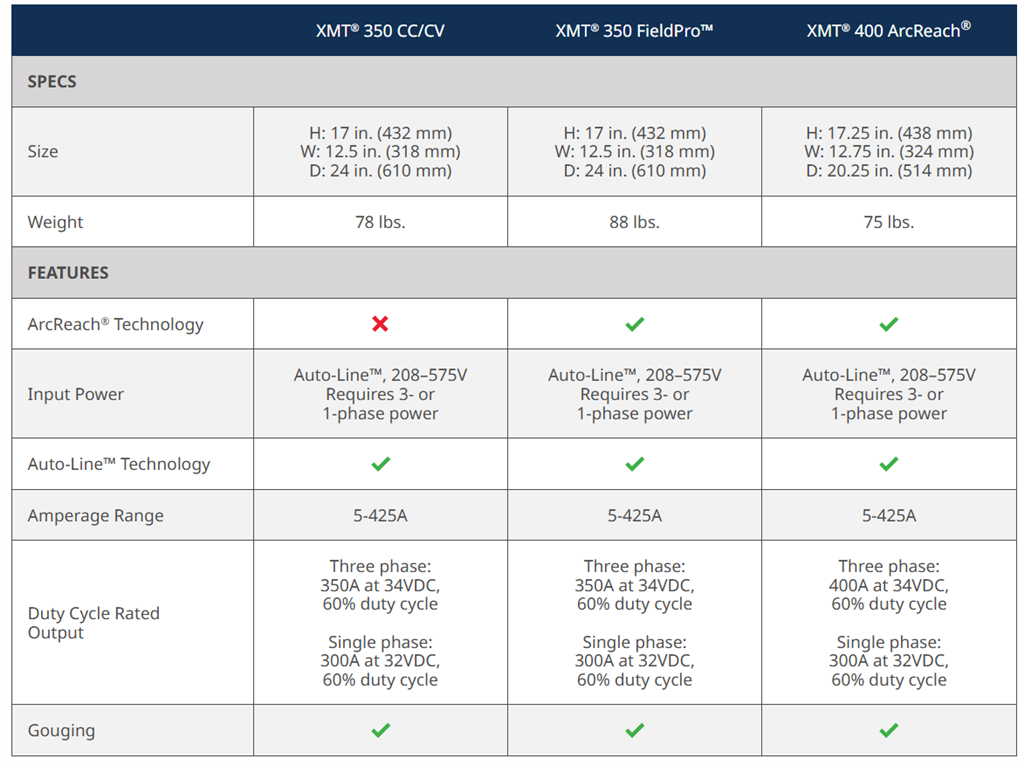

4. XMT® 400 ArcReach: Compact, Portable, and Powerful

The XMT® 400 ArcReach is a compact, lightweight multiprocess welder ideal for confab operations. Offering 400 amps at 60% duty cycle, it excels in delivering larger, longer welds with bigger wire and rods. Enhanced with ArcReach, Auto-Line, and CLC technologies, it ensures excellent arc stability and improved jobsite flexibility. Its portability and versatile features—supporting flux-cored, TIG, stick, and gouge welding—make it essential for a wide range of tasks. With a front panel lockout to maintain consistent settings, the XMT 400 boosts productivity and performance, making it a top choice for welders needing reliability and efficiency in demanding environments.

5. Induction Heating

Induction heating systems, like the ProHeat™ 35 and ArcReach® Heater, provide a safer and faster alternative to traditional open flame heating, offering precise heat treatment for welding applications, improving safety, and reducing energy consumption.

Embrace Technology for Enhanced Operations

As demand for skilled welders increases, embracing advanced welding technologies will help companies in Southeast Asia stay competitive. These innovations can address labor shortages, improve productivity, and ensure quality, enabling businesses to meet the fast-paced demands of the region’s growing industries. Investing in cutting-edge welding solutions will help companies maximize efficiency and stay ahead in today’s competitive market.

If you have more question, please reach out to us at SGOffice@MillerWelds.com.