Welding helmets are a vital component of a welder’s PPE. Welding helmets are primarily used to protect welders’ eyes during welding and grinding applications and to help them see the welding arc. There are thousands of welding helmets in the market, but not all helmets are created equal. The recent advancements in helmet technology not only help to enhance safety but also improve welder comfort and productivity. In this article, we will explore some of latest welding helmet technology in the market.

Auto-Darkening Welding Helmets

Traditionally, passive helmets have a dark lens that do not change. When using a passive helmet, the welder will have to nod the helmet down when the welding arc is initiated. Auto-darkening helmets offer greater convenience and ease of use because the welder no longer needs to raise and lower his helmet constantly. The auto-darkening lens automatically changes from a “light” state to a “dark” state when the sensors on the helmet detect the welding arc.

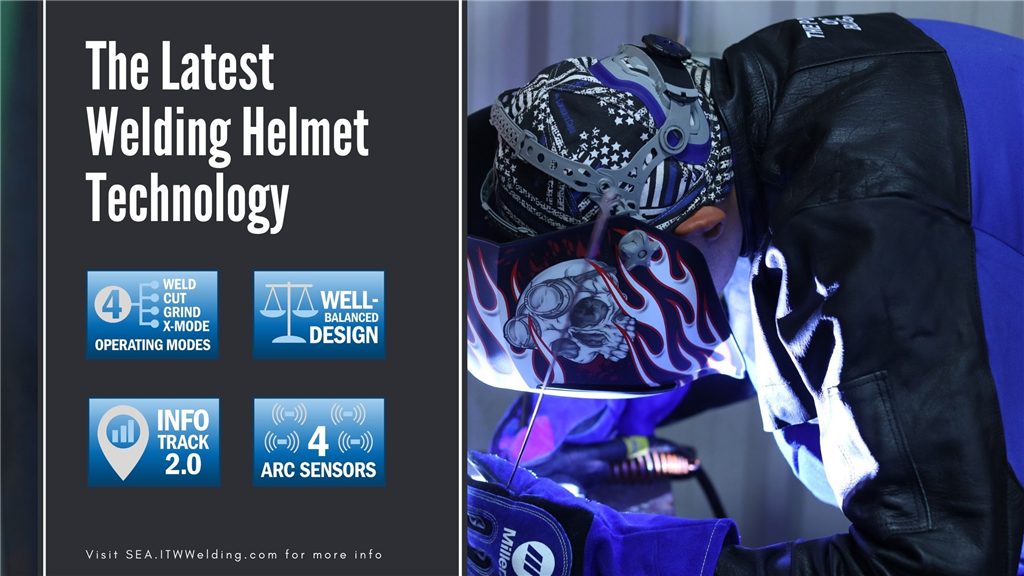

Auto-darkening helmets typically offer two more benefits over the passive helmets. Firstly, auto-darkening helmets can allow the welder to adjust the lens shade to match the brightness of the welding arc, which is extremely helpful when the welding processes vary. Secondly, auto-darkening helmets can also offer different operational modes besides welding, such as plasma cutting and grinding. This means that one helmet can be used for numerous jobs and applications.

Improved Clarity

The traditional lens filter technology prevents some colours from passing through. Consequently, welders usually see a yellow, green or blue tint, which can result in eye strain and welder fatigue after a long day at work. To address this issue, Miller Electric developed ClearLight Lens Technology that will allow more wavelengths along the colour spectrum to come through the helmet lens. This technology improves visibility by giving welders a clearer view of the weld pool and the surrounding workpiece while welding, thereby contributing to higher-quality welds and less rework. In addition, because ClearLight Lens Technology reduces eye strain, welders are able to leave their helmets on for a longer period of time, leading to greater efficiency and safety.

Arc Tracking Capabilities

Some welding helmets also come equipped with the ability to track arc-on-time, i.e., the amount of time a welder spends welding over a period of time. This information allows the company to calculate productivity levels and identify areas for improvement. Welders can also use this technology to set an alarm to keep track of daily activities or to receive alerts about breaktimes or shift changes.

Electromagnetic Arc Sensor

Despite the benefits of auto-darkening helmets over passive welding helmets, there are certain special circumstances where some auto-darkening helmets may not perform as expected. For example, when welding under bright sunlight, the auto-darkening lens may darken before the welder starts welding. Alternatively, when welding in confined spaces, the position of the welder’s head or a physical obstruction could block the helmet’s sensor and prevent the lens from darkening.

In order to overcome these challenges, Miller Electric developed X-Mode Lens Technology. X-Mode uses an electromagnetic sensor to pick up the magnetic frequency of the welding arc, and the lens will darken only when welding takes place. This technology eliminates any interference issues such as bright sunlight or obstacles, thereby improving welder productivity.

Ergonomic Headgear Design

Last but not least, newer welding helmets are designed with comfort in mind. Welders can wear a helmet for five or six hours a day, and a poorly designed and heavy helmet can affect their comfort and productivity levels. Newer welding helmets distribute the weight evenly across the welder’s head and help to alleviate strain and discomfort. In addition, next generation welding helmets are also designed with the thinnest and lightest materials available that do not compromise on safety or durability.

Make an Informed Decision

Welding helmets are important to ensure welder’s safety. However, many welding contractors do not put much thought into choosing the most appropriate welding helmet for their welders. If the latest welding helmet technology can help to improve welder comfort and productivity levels, will you make the switch?