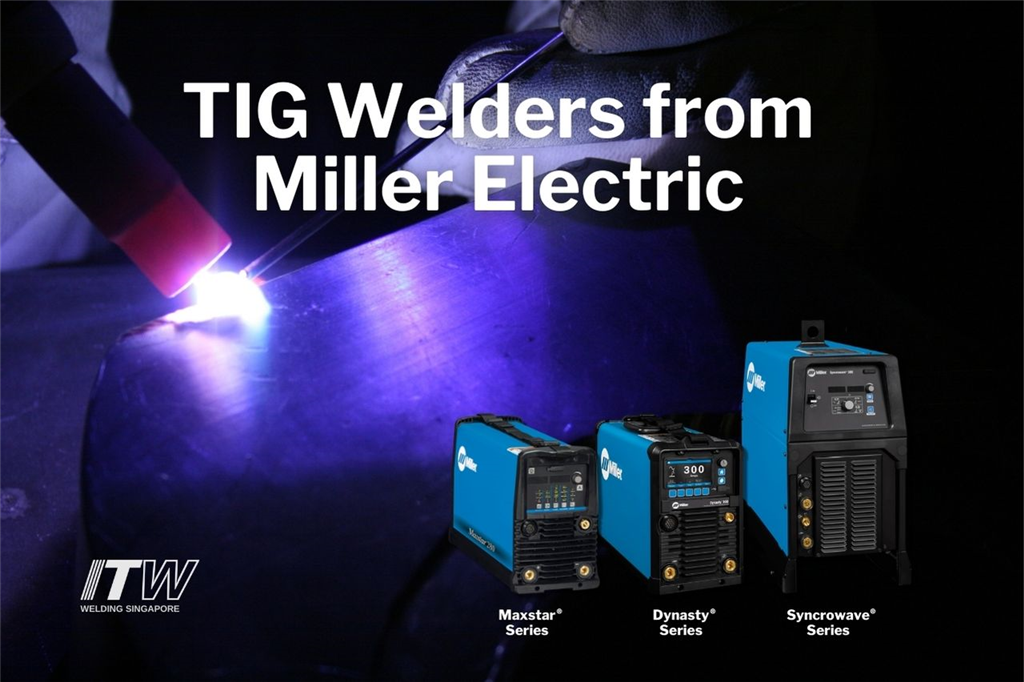

What is a TIG Welder?

TIG Welders, GTAW Machines and TIG Welding Machines are used interchangeably by many people. A TIG Welder is a welding machine that is designed mainly for TIG welding. You can perform TIG welding using Stick welding machines or Multiprocess welding machines, but in most cases, these welding machines only offer basic TIG welding features such as scratch start TIG and amperage control. For some welders, this rudimentary TIG welding might suffice. But for many welders who work in industries that demand precise, critical welds, a dedicated TIG Welder is usually the preferred choice. In this article, we will elaborate on three of the most popular TIG welding machines from Miller Electric: The Maxstar® series, Dynasty® series and Syncrowave® series.

Maxstar® Series TIG Welding Machines

The Maxstar® Welder is a DC-only TIG welding machine. This means that the Maxstar® can be used for welding steel and stainless-steel. The Maxstar® is commonly used in the oil & gas, petrochemical, power, and shipbuilding industries, for the welding of pipes and vessels. There are five main TIG Welders under the Maxstar® series.

- Maxstar® 161

- Maxstar® 210

- Maxstar® 280

- Maxstar® 400

- Maxstar® 800

Maxstar® 161 weighs only 5.9kg and is the most compact TIG welding machine in this series. It is ideal for welders who need to perform repair and maintenance jobs in the field. The Maxstar® 161 can deliver a rated welding output of 110A/14.4V/100% duty cycle. The Maxstar® 161 comes in two options, Maxstar® 161 STL and Maxstar® 161 STH. Maxstar® 161 STL allows for Lift-Arc™ start, while Maxstar® 161 STH allows for high-frequency (HF) arc starts and DC pulse TIG welding.

Maxstar® 210 and Maxstar® 280 are two of the most popular TIG Welders from the Maxstar® family. These compact welding machines can be used in both the shop and field, wherever precision TIG welding is required. The Maxstar® 210 has a rated welding output of 210A/18.4V/60% duty cycle, while the Maxstar® 280 has a rated welding output of 250A/20V/60% duty cycle. Both models are equipped with HF arc starts, Pro-Set™, Auto-Line™ Technology and DC pulse TIG welding. For welders who need more control and fine-tuning, the Maxstar® 210 DX and Maxstar® 280 DX provide additional features. These include shielding gas pre-flow, sequencer function, DC pulse wave shaping and extended DC pulse TIG capabilities.

The last two models in the Maxstar® family are the Maxstar® 400 and Maxstar® 800. These TIG Welders are meant to be used in the shop for heavy-duty fabrication and fixed automation applications, such as tube mills, cladding and pipe/vessel welding. The Maxstar® 400 has a rated welding output of 250A/30V/100% duty cycle, and the Maxstar® 800’s rated welding output is 500A/40V/100% duty cycle. Since these TIG welding machines are often used for automation applications, they are equipped with nine program memories and the ability to DC pulse at 5,000 pulses per second (PPS) for maximum travel speeds.

Dynasty® Series TIG Welding Machines

The Dynasty® Welder is an AC/DC TIG welding machine, which means it can be used to weld aluminum, steel, and stainless-steel. Simply put, the Dynasty® retains the capabilities of the Maxstar® but adds the ability to TIG weld aluminum. The Dynasty® series is widely used in industries such as aerospace, recreational boat fabrication, and truck & trailer manufacturing, just to name a few. There are four TIG welding machines under the Dynasty® series.

- Dynasty® 210

- Dynasty® 300

- Dynasty® 400

- Dynasty® 800

The Dynasty® 210 and Dynasty® 300 have undergone a revamp and were relaunched in 2022. The biggest change is that these two TIG welding machines now come with a 4.5-inch LCD display. This user-friendly interface provides informative on-screen explanations and dynamic images to ensure that welders set up the welding machine properly before welding. The Dynasty® 210 has a rated welding output of 210A/18.4V/60% duty cycle, while the Dynasty® 300 has a rated welding output of 250A/20V/60% duty cycle. Besides DC TIG and DC pulse TIG, the Dynasty® offers AC TIG for aluminum welding. Welders can adjust four main parameters of the AC waveform during AC TIG welding for added precision and control. These are AC Balance, AC Frequency, AC Waveshape, and Independent AC Amperage.

The Dynasty® 400 and Dynasty® 800 are built for heavy fabrication and automated applications that require higher welding outputs and duty cycles. For example, the Dynasty® 400 has a rated welding output of 250A/30V/100% duty cycle, while the Dynasty® 800 has a rated welding output of 500A/40V/100% duty cycle. Because the Dynasty® 400 and Dynasty® 800 can weld both aluminum, steel, and stainless-steel materials, they are ideal for shops that need the flexibility to TIG weld all materials.

Syncrowave® Series TIG Welding Machines

Miller Electric has been manufacturing TIG Welders under the Syncrowave® trade name for more than 45 years now. The Syncrowave® has a proud and rich history and most of the welders who have welded TIG would be familiar with the Syncrowave® name. As welding technology continues to evolve, and the needs of the new welders change over time, Miller Electric introduced the latest generation of the Syncrowave® series in 2020, the Syncrowave® 300 and Syncrowave® 400.

Syncrowave® 300 and Syncrowave® 400 are AC/DC TIG welding machines that can weld all materials, including aluminum. These machines are meant to be used on the shop floor for general fabrication applications and are also popular in vocational training schools. The Syncrowave® 300 has a rated welding output of 300A/22V/30% duty cycle, and the Syncrowave® 400 has a rated welding output of 400A/26V/30% duty cycle. Compared to the Syncrowave® of old, the new Syncrowave® 300 and Syncrowave® 400 are inverter-based welding machines that offer better energy efficiency and a smaller footprint. The new Syncrowave® 300 & 400 also have a simple and intuitive user interface, making it easy for welders to adjust parameters.

Choosing the Correct Miller® TIG Welder

Selecting the best TIG welding machine for your welding application does not need to be difficult. If you need further clarifications or recommendations, do reach out to us at SGOffice@MillerWelds.com for a discussion.