Advanced orbital welding machines from Orbitalum, such as the Orbimat Smart Welder, are equipped with a unique Digital Gas Control Function. The Digital Gas Control Function is made up of 2 key features, Flow-Force and Permanent-Gas. These features help welding contractors reduce weld cycle time and costs.

Flow-Force

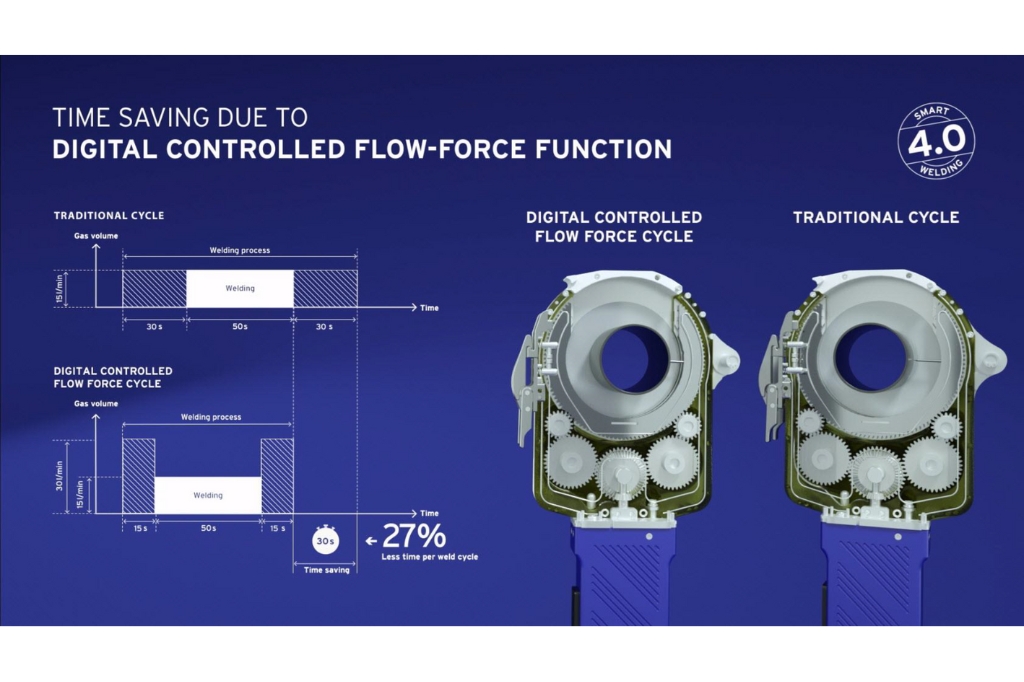

Flow-Force is a unique OD purging feature that dramatically reduces weld cycle time. A weld cycle is made up of 3 components: Pre-purge time, Arc-on time and Post-purge time. Pre-purge creates an inert environment in the weld head chamber prior to welding, ensuring high-quality welds. Post-purge minimizes the oxidation of the weld bead and tungsten electrode after the arc is terminated.

Traditionally, the pre-purge and post-purge durations tend to be long, resulting in extended weld cycles and reduced productivity. The exclusive Flow-Force feature from Orbitalum can reduce purging time by increasing the purging flow rate. In this example below, the time savings is 30 seconds, or a 27% reduction in the weld cycle time.

When Flow-Force is activated, welding contractors will notice several benefits including reduced time per weld, increased arc-on time, higher number of welds per shift, decreased weld head temperatures, and an extended service life for the tungsten electrode.

Permanent-Gas

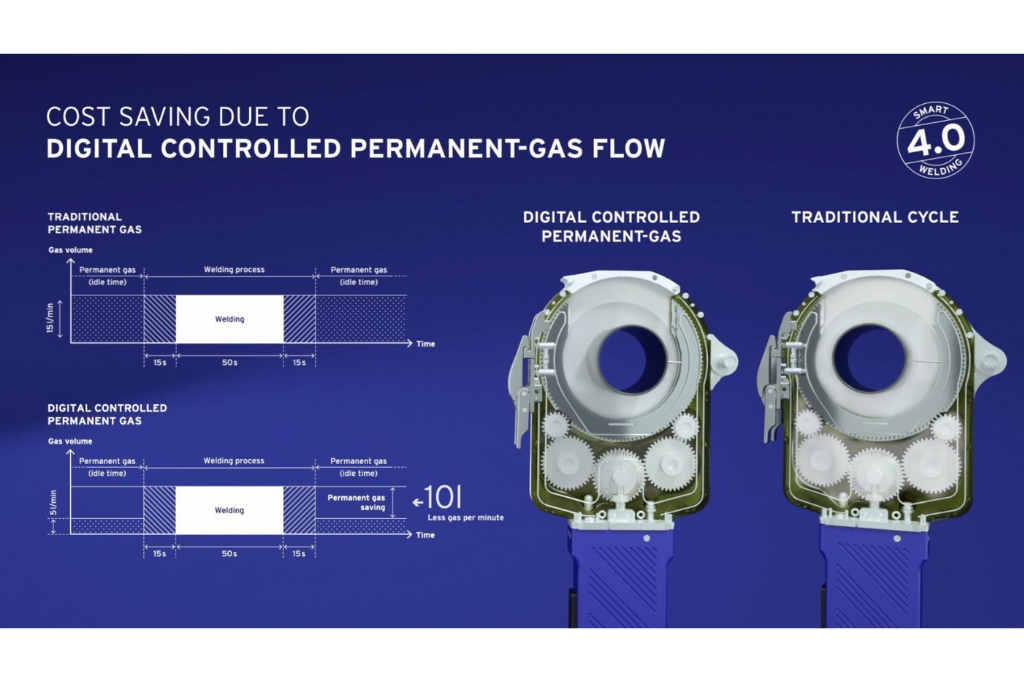

As welders transition between orbital weld joints, it is typical for them to maintain the flow of shielding gas. Failure to do so can allow oxygen to infiltrate the weld head, leading to subpar weld quality. Nonetheless, this practice results in significant daily wastage of shielding gas.

Orbitalum's Permanent-Gas feature is designed to guarantee welds free from oxidation while also cutting down on shielding gas usage. Upon activation of this feature on the orbital welding machine, a controlled, low-flow positive purge gas pressure is established within the weld head. For instance, in the example provided below, this feature can save up to 10 litres of shielding gas per minute.

If you want to reduce your orbital welding cycle time or shielding gas consumption, reach out to us at sherwyn.tan@orbitalum.com to request a demo.