Orbitalum, a leader in orbital welding technology, offers closed weld heads designed for high-quality, repeatable welds essential in industries like semiconductor manufacturing, aerospace, and pharmaceuticals. These closed weld heads provide a controlled environment around the weld joint, protecting it from contaminants and ensuring consistent results.

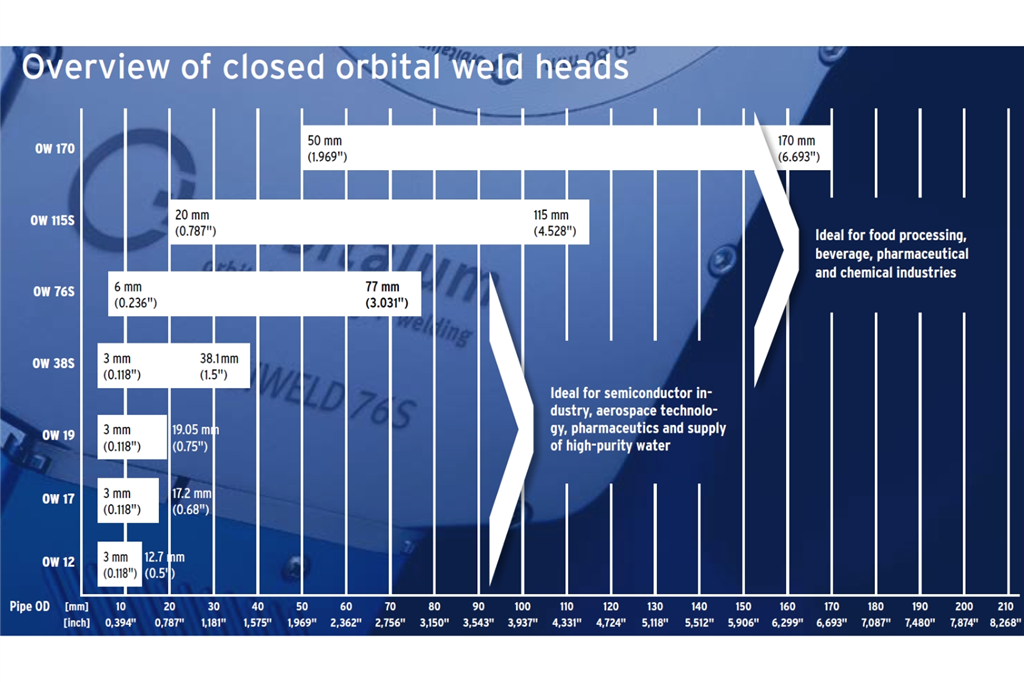

There are 2 main differences amongst all the closed weld heads from Orbitalum. The first would be the outer diameter (OD) of the tube to be welded. The second would be the design of the closed weld head.

The Orbitalum Orbiweld 12 (OW12) has an extremely narrow design that makes it ideal for working in tight spaces and for the orbital welding of common micro fittings.

- The OW12 can weld a tube OD of 3.0mm to 12.7mm, or 0.118” to 0.500”.

- The design of the closed weld head consists of a removal clamping cartridge.

The Orbitalum Orbiweld 17 (OW17) has an integrated liquid-cooling system, allowing for higher duty cycles and lower production downtime.

- The OW17 can weld a tube OD of 3.0mm to 17.2mm, or 0.118” to 0.677”.

- The design of the closed weld head consists of a removal fixture block.

- A gas-variant, known as the OW17 GC, is available as well.

The Orbitalum Orbiweld 19 (OW19) can be used in very tight spaces because the clamping mechanism does not project beyond the head outline, even when the clamps are opened.

- The OW19 can weld a tube OD of 3.0mm to 19.05mm, or 0.118” to 0.750”.

- The closed weld head uses a scissors clamping design, allowing for single-handed operations.

- A heavy-duty option, known as the OW19 HD, is also available. Existing OW19 weld heads can be converted to the OW19 HD with a conversion kit.

The Orbitalum Orbiweld S series closed weld head consists of OW38S, OW76S and OW115S. Because of the highly efficient cooling mechanism, these weld heads enjoy a narrow design. This gives better accessibility to the joint to be welded, as well as a higher duty cycles for minimal production downtime.

- The OW38S can weld a tube OD of 3.0mm to 38.1mm, or 1/8” to 1.5”.

- The OW76S can weld a tube OD of 6.0mm to 77.0mm, or 1/4” to 3.0”.

- The OW115S can weld a tube OD of 20.0mm to 115.0mm, or 3/4” to 4.5”.

- These closed weld heads use a two-sided clamping design.

The Orbiweld 170 (OW170) is the largest closed weld head that is manufactured by Orbitalum. Its excellent heat dissipation allows for continuous orbital welding operations in the shop and the field.

- The OW170 can weld a tube OD of 50.0mm to 170.0mm, or 2” to 6”.

- This closed weld head uses a two-sided clamping design.

The Orbiweld X (OWX) series is a next-generation orbital weld head from Orbitalum. Some key features include an integrated LED lighting, a digital display with smart functions, and an inbuilt gyro sensor.

- The OWX3.0 can weld a tube OD of 6.0mm to 77.0mm, or 0.25” to 3”.

- This closed weld head uses an improved two-sided clamping mechanism.

Want to solve an orbital welding challenge? Or interested to see a demonstration of the closed weld heads from Orbitalum? If you are based in Southeast Asia (Singapore, Malaysia, Thailand, Indonesia, Vietnam etc.), reach out to sherwyn.tan@orbitalum.com