In orbital welding, achieving a good weld is only one piece of the puzzle. Having complete traceability of the weld is equally important. Additionally, with the advancement in technology, many customers also want to integrate their orbital welding machines into their manufacturing operations. In this article, we will elaborate on the Standard and Upgradeable features that our flagship OM180SW orbital welding machine offers to improve traceability and integration.

Standard Product

The standard OM180SW provides 3 easy-to-use features to improve traceability:

- Standard Documentation

- Documentation Process

- QR Scan Basic Text

Standard Documentation

After performing an orbital weld, a weld log file is generated to allow for proper traceability. Traditionally, the printer that is integrated in the welding machine prints out the weld log file after each weld. This piece of paper is collected by the QA/QC who then manually compiles all the data in an excel spreadsheet for submission to the client.

There is a built-in printer on the OM180SW orbital welding machine that can print the weld logs. Alternatively, since the OM180SW has 4 USB ports, the softcopy weld logs can also be automatically saved onto a USB thumb drive in both excel and PDF formats after each weld. This reduces the workload significantly for the QA/QC. Additionally, traceability is improved because the risk of human error during data collection can be minimized.

Video link: https://www.youtube.com/shorts/F24nk0CaqfQ

Documentation Process

For each orbital weld, it is important to note that the QA/QC team would like to collect more data beyond the welding parameters that are stated in the weld log. Such additional data can include the Welder Identification, Project Name, Material Heat Number etc. Traditionally, this information is manually written down by the welder on a piece of paper, which the QA/QC will have to collect and compile into an excel spreadsheet for submission to the client.

To eliminate this cumbersome process, Orbitalum came up with a feature called Documentation Process. Before starting each orbital weld, the welder must key in this vital information requested by the QA/QC. Failure to do so means that the welder will not be able to start the orbital welding process. Once the orbital welding is completed, all these additional data such as Welder Identification and Material Heat Number will be saved in the weld log file, for improved traceability.

Video link: https://www.youtube.com/shorts/YLQ-WI8zkTM

QR Scan Basic Text

To fill in the documentation fields such as Welder Identification, Project Name, Material Heat Number etc., a welder has a few options. The traditional method will be to use the touchscreen keypad on the OM180SW or use the physical keyboard to enter the details.

Alternatively, if you want to achieve higher efficiency and minimize mistakes, you can convert the text to a QR code. This QR code can be scanned using a barcode scanner that is connected to one of the USB ports on the OM180SW.

Video link: https://www.youtube.com/shorts/v1Ce-kg4s70

Upgraded Product

Besides the abovementioned standard features, the OM180SW can also be upgraded with our Connectivity Package (a software license key) to unlock the following IoT 4.0 features:

- QR-Scan Remote Commands

- LAN Shared Folder

- MQTT

- VNC

QR-Scan Remote Commands

If you want to have an even tighter control over your manufacturing operations, you can create command strings that will instruct the OM180SW on what to do. For example, the command string could be to automatically load a specific weld program from the OM180SW. This command string can be converted to a QR code, and the welder can scan the QR code with the barcode scanner and execute the command on the OM180SW. This minimizes the risk that the welder will select the wrong weld program during the welding operation.

With this QR-Scan Remote Command feature, you can also use the barcode scanner to efficiently create documentation fields, fill in documentation fields and navigate amongst the Menu, Weld Mode and Test Mode on the OM180SW.

Video link: https://www.youtube.com/shorts/tFxxI31_ii8

LAN Shared Folder

To further improve traceability, the OM180SW can be connected to the company’s server via LAN or WLAN. Welding engineers can upload weld programs onto the LAN shared folder via their laptops, which are also connected to the company’s server. Welders can find the weld programs on the OM180SW and load them for welding. After welding, all weld log files are saved directly on the LAN shared folder. This eliminates manual data collection via printouts and USB sticks.

Video link: https://www.youtube.com/watch?v=APtdjbc_KBI

MQTT

MQTT stands for Message Queuing Telemetry Transport. This is an open sourced, customizable software. This software tool allows you to transfer multiple points of data to and from the OM180SW welding machine, instantaneously.

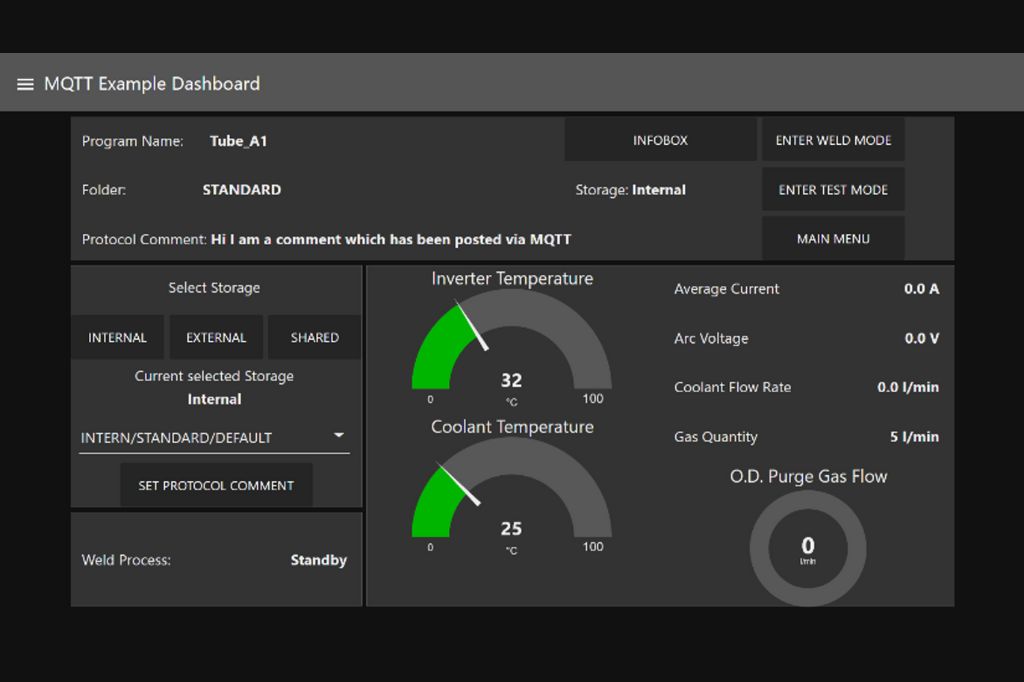

With a simple dashboard, you can use MQTT to live monitor any parameter of data the machine creates. Here you see a dashboard monitoring multiple live points of data, such as temperature, arc voltage, current, purge gas flow rates, storage location of log files, etc. Simply put, MQTT allows you to capture any information from the welding machine that is vital to you and integrate this information into your manufacturing operation dashboard for better command and control.

VNC

VNC stands for Virtual Network Computing. From the laptop or tablet, the engineer can control all functions on the OM180SW except any function that results in the movement of fluids or mechanical components. For example, you cannot perform a gas test or start a weld for safety reasons. VNC could be useful if the welding engineer or service engineer would like to have remote access to the welding machine.

Video link: https://www.youtube.com/watch?v=BxJ9k_qZJfc

Want to see a demo on these features in Southeast Asia and Oceania? Reach out to sherwyn.tan@orbitalum.com