In this article, we answer some of the common questions that metal fabricators tend to have about MIG welding gun consumables. If you have a burning question, feel free to reach out to us at SGOffice@MillerWelds.com

What Are the Common MIG Welding Gun Consumables?

The three most common MIG welding gun consumables are the diffuser, contact tip and nozzle. The diffuser attaches directly to the gun neck and carries current through to the contact tip. It also directs the shielding gas into the nozzle. The contact tip transfers the current from the diffuser to the wire as it guides the wire through the nozzle and to the weld puddle. Finally, the nozzle connects to the diffuser and helps to keep the shielding gas focused on the welding arc and puddle.

How Should Mig Welding Gun Consumables Be Stored?

Diffusers, contact tips and nozzles should always be stored in their original packaging until they are ready for use. Opening them and placing them in a bin can lead to scratches or dents, which may allow spatter to adhere more easily, thereby shortening the products’ lifespan.

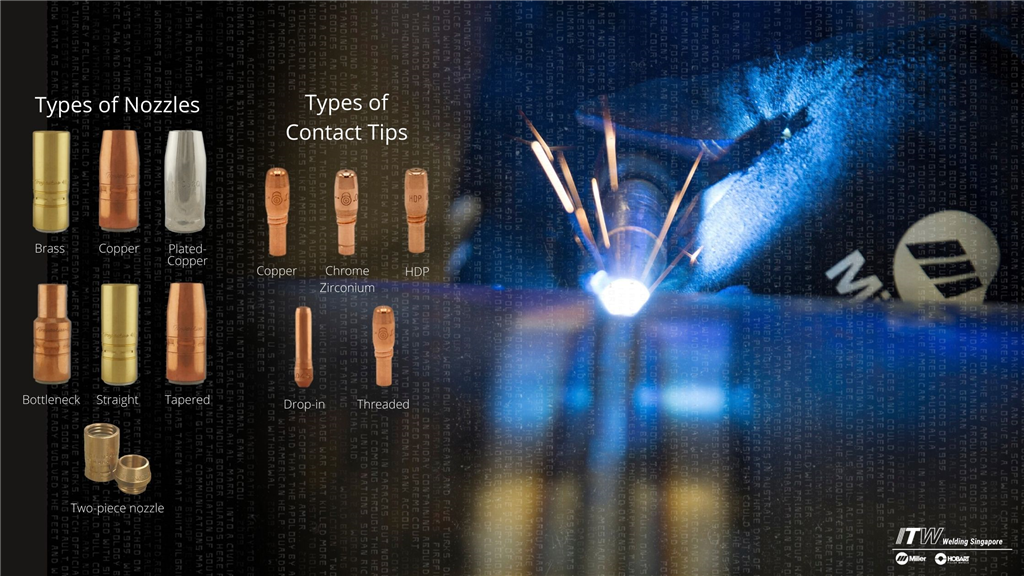

What Are the Different Types of MIG Welding Gun Nozzle?

Nozzles differ in material, shape, and connection style to meet the needs of different welding applications. There are usually three materials to choose from. Brass is ideal for applications between 100-300 amps. Copper is better for applications that require more than 300 amps. Chrome-plated or nickel-plated copper nozzles provide good spatter resistance and can be used for high amperage applications. As for nozzle shapes, there are also three different varieties. Straight nozzles offer good shielding gas flow but may not provide enough access to some welds. For improved weld access, bottleneck nozzles or tapered nozzles may be a better choice. Lastly, the three most common nozzle connection styles are slip-on, thread-on and two-piece. Slip-on nozzles slide onto the gas diffuser and are much faster and easier to replace compared to thread-on nozzles. A two-piece nozzle comprises of a nozzle body and a cone, thereby allowing the replacement of just the cone since it is the primary area of wear. This helps to lower consumable costs.

What Are the Different Types of MIG Welding Gun Contact Tips?

Contact tips differ in material and connection style. Copper contact tips are the most common and are suitable for most applications. For more demanding welding applications, Chrome zirconium contact tips can be used. For robotic welding applications that tend to use the pulsed MIG welding process, Tregaskiss® offers HDP contact tips that can last 6-10 times longer than copper and chrome zirconium contact tips. As for connection style, there are usually two types, threaded and drop-in. Threaded contact tips screw into the diffuser and are tightened with welding pliers. Drop-in contact tips are threadless and are held in place by the nozzle.

When companies purchase contact tips, they usually focus on the price per tip. However, it’s important to look beyond the initial price and consider the big picture, which includes the downtime and labour required for changeover, as well as any quality issues that may arise from the use of low-quality tips.

Take Care of Your MIG Welding Gun Consumables

Regularly inspecting and cleaning the MIG gun consumables is critical to ensuring weld quality. For example, a nozzle that becomes clogged by spatter can restrict shielding gas flow and lead to porosity in the weld.