In this article, we will discuss the four different submerged arc welding polarities, namely DCEP, Sinusoidal AC, DCEN and VBAC. We will also elaborate on how each polarity influences weld penetration, deposition rate, parent metal dilution, and arc stability.

Direct Current Electrode Positive (DCEP)

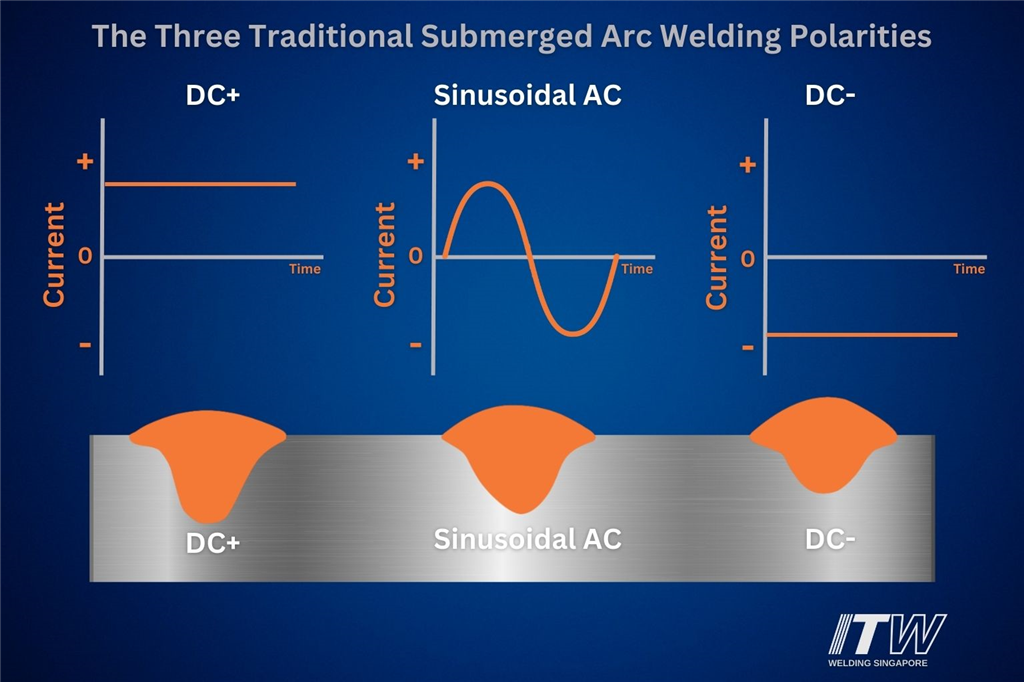

With DCEP, or DC+, because most of the heat is developed at the surface of the weld pool, it gives the deepest weld penetration and highest parent metal dilution. DC+ also gives a stable arc, an optimal weld appearance and a good weld profile. For these reasons, DC+ is commonly used for single-wire and twin-wire submerged arc welding applications, and for the leading wire in multiple-wire operations.

However, there are three limitations with DC+. Firstly, the weld penetration can be too deep for the root pass, causing burn-through. Secondly, DC+ is sensitive to magnetic arc blow. Lastly, with DC+, low heat input and high deposition rates cannot be obtained at the same time without sacrificing bead appearance.

Traditional Sinusoidal Alternating Current (AC)

Traditional sinusoidal AC gives approximately 15% higher deposition rate than DC+, shallower weld penetration and lower parent metal dilution. Sinusoidal AC is commonly used for trailing wires in multiple-wire submerged arc welding systems to counteract magnetic arc blow and to increase deposition rate.

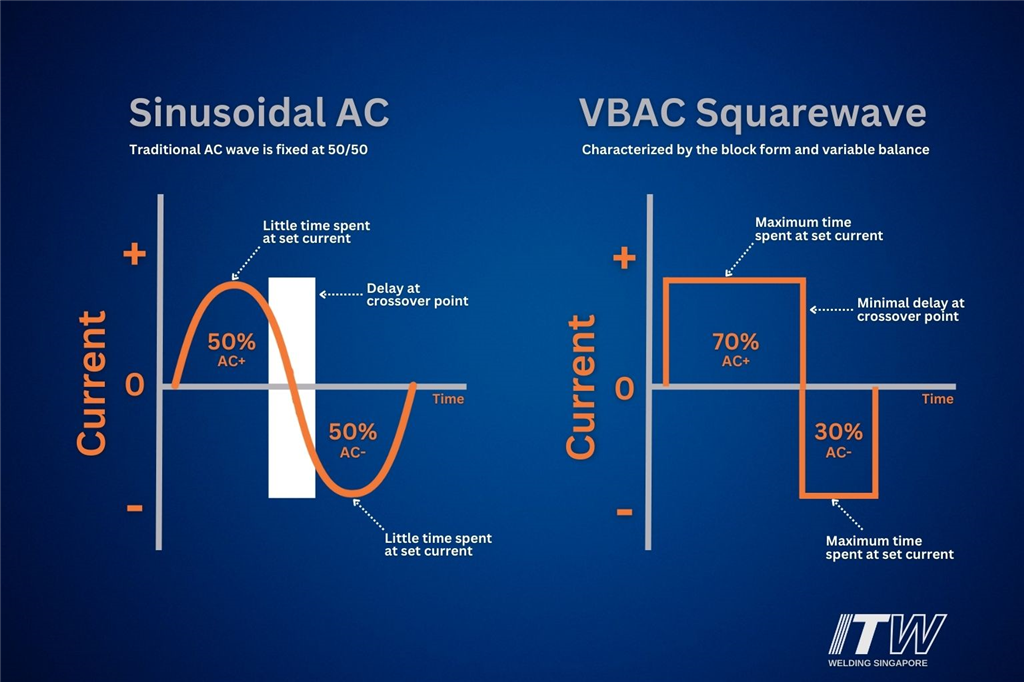

A disadvantage of conventional sinusoidal AC is poor arc ignition and arc stability because the current passes through the zero point with a certain delay. Another drawback is that a low percentage of time is spent at the set amperage, which means lower deposition rates and productivity. Lastly, with traditional sinusoidal AC, the AC+/AC- ratio is fixed at 50/50 and cannot be adjusted for different applications.

Direct Current Electrode Negative (DCEN)

DCEN, or DC-, delivers approximately 35% higher deposition rates than DC+ because most of the heat is developed at the tip of the wire electrode. When DC- is used, weld penetration and parent metal dilution is low. The main application for DC- is strip cladding, where dilution with the parent metal needs to be limited.

Variable Balance Alternating Current (VBAC) Squarewave

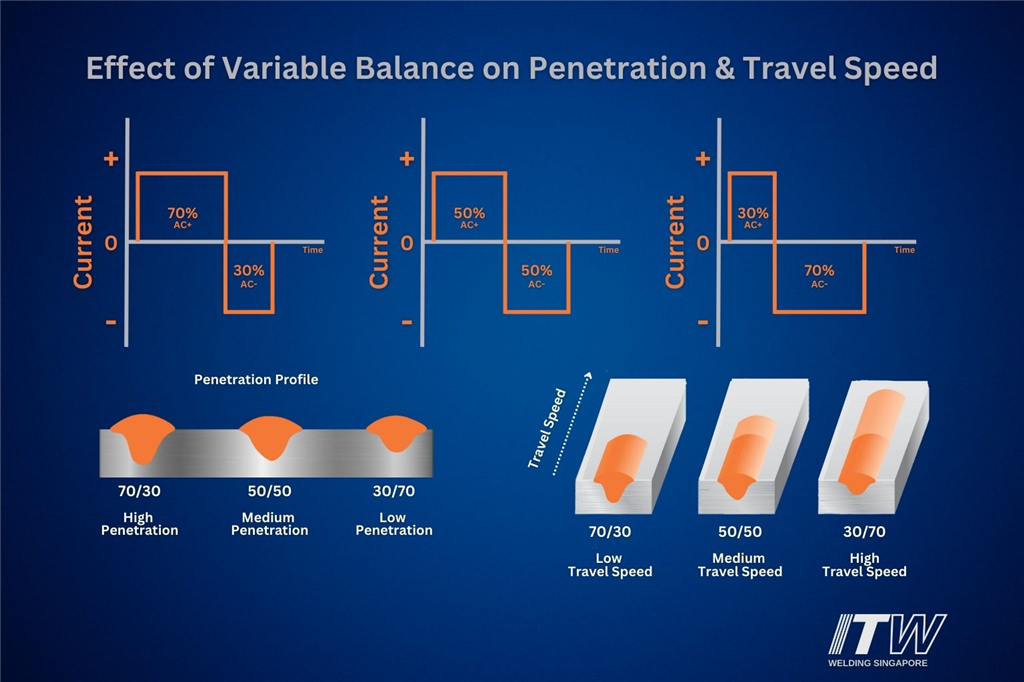

Modern submerged arc welding machines, such as the Miller® SubArc AC/DC 1250 Digital, are equipped with VBAC squarewave technology. VBAC squarewave technology has two main advantageous properties — the AC wave block form and the AC wave variable balance. Because of the AC wave block form, the current passes through the crossover area in milliseconds. This results in good arc starts and arc stability and more dwell time at set current. On the other hand, the AC wave variable balance makes it possible to alter the share of AC+ and AC- to any desired ratio. Increasing the AC+ share will give deeper penetration and reduced deposition, while increasing the AC- share will do the opposite.

The Benefits of VBAC Squarewave

Compared to traditional DC+ and conventional sinusoidal AC, VBAC squarewave technology offers multiple advantages in single-wire and multiple-wire submerged arc welding applications. Firstly, with VBAC, the root penetration and deposition rate can be fine-tuned, allowing fabricators to minimize chances of burn-through at the root pass. Secondly, because of its AC wave block form and variable balance, VBAC delivers higher deposition rates, resulting in higher productivity. Lastly, a higher deposition rate also allows for a higher travel speed and a reduction in heat input, which helps improve mechanical properties and reduce distortion.

.jpg)

If you’ll like to see a demo on the Miller® VBAC squarewave technology and how it can help to improve your submerged arc welding productivity, reach out to us at SGOffice@MillerWelds.com